Not your father’s typical steel mill

At CMC, we’re proud of our heritage, but we’re even prouder of the innovative and pioneering spirit that has set us apart from our competitors and taken our mill operations and our products to new heights. Automation and environmentally friendly process advancements have revolutionized the way CMC makes steel.

We’re also proud of our superior team of dedicated steelmaking professionals who are committed to understanding your needs, developing custom solutions and delivering quality products.

CMC Steel’s state-of-the-art mills produce world-class products

- Nine mills strategically located across the U.S.

- Melt capacity to produce over 5 million tons of finished long steel products

- Flexibility and capability to offer the variety of steel products

- Electric arc furnace (EAF) mini and micro mill technology provides unmatched quality and immediate access to a wide inventory of products.

Our mills produce steel long products including rebar, angles, channels, flats, rounds, squares, post, wire rod and other special sections. For detailed product information, download the Mill Products Guide.

The Raw Materials Department is responsible for all scrap purchases for CMC Steel. For information on scrap pricing or other related scrap information through the mill directly, please click here.

Mill Products

Performance Reinforcing Steel

Steel mill innovation results in high-quality products

CMC advanced the latest innovation in steel-making technology using a continuous process at our EAF micro mills in Mesa, Arizona and in Durant, Oklahoma. Pioneered by CMC, we are the first steelmakers in the world to successfully operate technology of this type. This innovative continuous process melts, casts and rolls steel from a single uninterrupted strand, producing higher strengths and lower energy costs compared to traditional mini mill processes.

In addition to our U.S. micro and mini mill facilities, we operate the second largest long-products EAF mini mill in Poland. The EAF steelmaking technology is the cleanest and most energy-efficient steelmaking process available today.

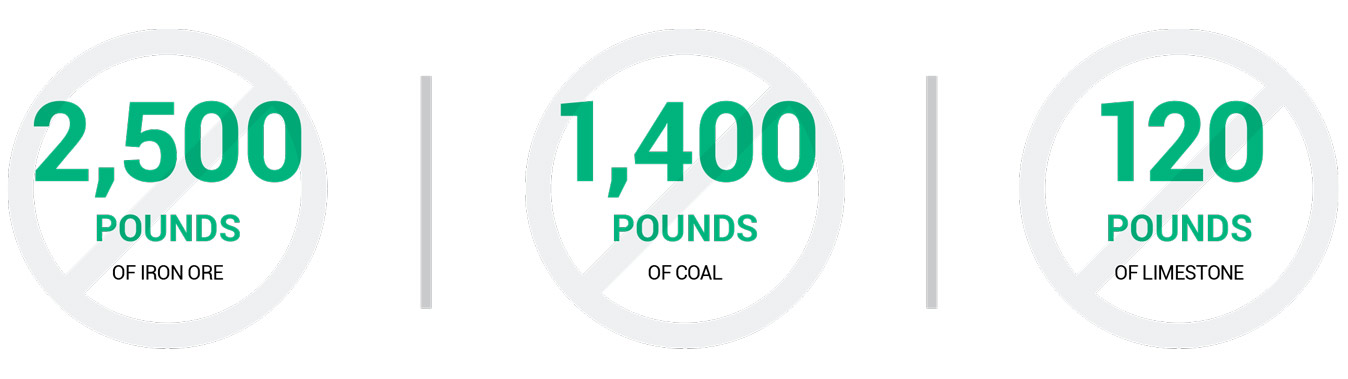

By using recycled scrap as our raw material, we reduce the need for mining natural resources. In addition, by operating our mills with innovative electric arc furnace technology rather than conventional blast furnaces, our CO2 emissions are 63% less than the global steelmaking industry average, further helping to preserve our natural resources while still producing high-quality products. Our steel is utilized in numerous applications including infrastructure, construction, agriculture, manufacturing, service centers and fabrication businesses.

For every ton of steel produced, we avoid the use of:

Quality

CMC is committed to working closely with our customers to ensure their product requirements are successfully met. We aim to deliver only the highest quality products and the best customer service. Compliant with ISO 9001 Quality Management Systems, we also maintain an Integrated Management System and continuously work to improve all aspects of our business.

Ensuring that all our steel products meet strict quality standards is our pledge to customers. We work daily to ensure our mills produce steel in conformance with all applicable codes and specifications including:

- ASTM

- ASME

- AASHTO

- SAE/AISI

- Military Specifications

- Canadian Specifications

CMC Steel Alabama — Birmingham, AL

Products

Equal AnglesUnequal Angles

Channels

Flats

Billets

Certifications

CMC Steel Alabama’s Quality Management System (QMS) is registered to ISO 9001:2015 for the manufacture and supply of steel shapes, bars and billets. In addition, our QMS is in compliance with the following quality programs:

CMC Steel Arizona — Mesa, AZ

Products

Rebar

Spooled Rebar

T-Post Stock

Grape Stakes

Certifications

CMC Steel Arizona’s Quality Management System (QMS) is modeled after the ISO 9001:2008 and is in compliance with the following quality programs:

CMC Steel Arkansas — Magnolia, AR

Products

Equal Angles

Unequal Angles

Flats

Rounds (please inquire)

Rebar

T-Post Stock

Special Shapes

Certifications

CMC Steel Arkansas' Quality Management System (QMS) is modeled after the ISO 9001:2015 and is in compliance with the following quality programs:

CMC Steel Florida — Jacksonville, FL

Products

Rebar

Coiled Rebar

Wire Rod

Certifications

CMC Steel Florida’s Quality Management System (QMS) is modeled after the ISO 9001:2008 and is in compliance with the following quality programs:

NTPEP/AASHTO

NQA-1

CMC Steel New Jersey — Sayreville, NJ

Products

Rebar

Certifications

CMC Steel New Jersey’s Quality Management System (QMS) is registered to ISO 9001:2015 for the manufacture and supply of steel shapes, bars and billets. In addition, our QMS is in compliance with the following quality programs:

CMC Steel Oklahoma — Durant, OK

Products

Rebar

Spooled Rebar

T-Post Stock

Grape Stakes

Certifications

CMC Steel Oklahoma's Quality Management System (QMS) is modeled after the ISO 9001:2008 and is in compliance with the following quality programs:

CMC Steel South Carolina — Cayce, SC

Products

Equal Angles

Unequal Angles

Channels

Flats

Rounds

Squares

Rebar

T-Post Stock

Special Shapes (please inquire)

Billets

MBQ

Certifications

CMC Steel South Carolina’s Quality Management System (QMS) is registered to ISO 9001:2015 for the manufacture and supply of steel shapes, bars and billets. In addition, our QMS is in compliance with the following quality programs:

ABS - QA System Approval

ABS - Facility and Process Approval

NTPEP/AASHTO

ISO 9001:2015

NQA-1

CMC Steel Tennessee — Knoxville, TN

Products

Rebar

Certifications

CMC Steel Tennessee’s Quality Management System (QMS) is modeled after the ISO 9001:2008 and is in compliance with the following quality programs:

NTPEP/AASHTO

NQA-1

CMC Steel Texas — Seguin, TX

Products

Equal Angles

Unequal Angles

Channels

Flats

Rounds

Squares

Rebar

T-Post Stock (please inquire)

Special Shapes (please inquire)

Billets

SBQ (please inquire)

Certifications

CMC Steel Texas’ Quality Management System (QMS) is registered to ISO 9001:2015 for the manufacture and supply of steel shapes, bars and billets. In addition, our QMS is in compliance with the following quality programs:

.jpg)

Mill Sales Contact Info

| Alabama | P: 800.621.0262 | millsales-al@cmc.com |

| Arizona | P: 888.641.8956 | millsales-az@cmc.com |

| Arkansas | P: 800.258.0022 F: 870.235.9296 |

millsales-ar@cmc.com |

| CARD | P: 888.641.8956 | millsales-ca@cmc.com |

| Florida | P: 888.870.0766 | millsales-fl@cmc.com |

| New Jersey | P: 888.870.0766 | millsales-nj@cmc.com |

| Oklahoma | P: 800.227.6489 | millsales-ok@cmc.com |

| South Carolina | P: 800.621.0262 | millsales-sc@cmc.com |

| Tenessee | P: 888.870.0766 | millsales-tn@cmc.com |

| Texas | P: 800.227.6489 | millsales-tx@cmc.com |

Mill Locations

Industry Links

Trade Associations

CMC participates in these organizations to help promote and improve the construction industry. We have employees across the country engaged and contributing to the following associations:

The Associated General Contractors of America (AGC)

American Concrete Pavement Association (ACPA)

Steel Manufacturing Association (SMA)

Metal Service Center Institute (MSCI)

Precast Concrete Institute (PCI)

Metal Building Manufacturers Association (MBMA)

American Institute of Steel Construction (AISC)

Association for Iron & Steel Technology (AIST)

Codes and Standards Bodies

The groups below are among those that write building code, set material testing requirements, and create standards for construction applicable to projects across the United States. CMC participates in these bodies to contribute ideas and processes towards the standards they create.

American Concrete Institute (ACI)

American Society of Testing Materials (ASTM)

Concrete Reinforcing Steel Institute (CRSI)

American Association of State Highway and Transportation Officials (AASHTO)